Insights

- The manufacturing sector has identified streamlining product design and development as the most impactful use case for generative AI.

- Manufacturing spent more than $1 billion on generative AI in 2023, with this spend projected to grow to $2.4 billion in 2024.

- There are ethical obstacles such as potential copyright violations and intellectual property infringement that need to be overcome for generative AI to scale upward.

- Our recommendations for ethical, responsible AI are classified into strategic, tactical, and governance approaches that must work in tandem.

- Humans trained in the nuances of generative AI will be essential to address the concerns over ethics, bias, explainability, hallucinations, and the variations in the output produced.

Businesses are moving from AI experimentation to working out how to extract value from the technology, identifying use cases spanning new product design and demand forecasting to end-of-life management (Figure 1).

The manufacturing sector has identified streamlining product design and development as the most impactful use case for generative AI, according to recent Infosys research. More than a third of the participants in the Infosys Generative AI Radar reports pointed to this as the use case with the most positive impact, as shown in examples across manufacturing.

The manufacturing sector has identified streamlining product design and development as the most impactful use case for generative AI

This upward trend in generative AI spending is evidence of its growing popularity. At the same time, there are ethical obstacles such as potential copyright violations and intellectual property (IP) infringement that need to be overcome for generative AI to scale upward.

Workflows should be redesigned around the unique strengths of humans and machines, while other tasks can be automated using AI and employees trained and upskilled for AI usage.

In this report, we also address the different data types that underpin generative AI and review use of both structured and unstructured data. Finally, we conclude with recommendations to address challenges with generative AI adoption.

Figure 1. Generative AI use cases across the product life cycle

Source: Infosys Knowledge Institute

Rise in spending

Generative AI spending in the sector is growing, thanks to compelling use cases such as automated quality assurance and AI-powered predictive maintenance. The manufacturing sector spent more than $1 billion on generative AI in 2023, with this spend projected to grow to $2.4 billion in 2024 (Figure 2).

This level of spending shouldn’t come as a surprise. Manufacturers are typically early adopters of new technologies. However, even with industry growth expected to slow due to geopolitical dynamics and the consumer shift from goods to services, the manufacturing sector still expects to double its generative AI spending in 2024, from our study findings. This signifies that manufacturers don’t view generative AI as a flash in the pan but as a critical tool to the present and future of manufacturing.

Figure 2. Expected generative AI spend in 2024, by industry and for manufacturing

Source: Infosys Knowledge Institute

AI for product innovation

In aeronautics, NASA uses AI to design spacecraft and mission hardware. Airbus has expanded the availability of generative AI beyond its initial users in engineering and data science to the wider business, identifying some 600 use cases, which the aircraft manufacturer says offer enormous potential in terms of efficiency, savings, and quality. For example, generative AI has been used to develop lighter aircraft parts that could sharply reduce carbon emissions.

“Generative AI can be used to spur creative approaches to the design of future aircraft. It may have the potential to develop novel aircraft structures with better aerodynamic properties and performance profiles. It can lead to advances in material science with lightweight, composite materials. It may even help with the design of sustainable aviation fuels,” Professor Mykel Kochenderfer of Stanford University said during a visit to Infosys’s Bengaluru campus.

In the automotive sector, Nissan’s front grille design for its new model Qashqai is a recent example of generative AI for product development. The grille is both an aesthetic part of the overall design and has cooling and aerodynamic requirements. Several iterations were possible, balancing the aesthetic and performance requirements to decide the best configuration.

Following new product design, enhanced user experience is the next most important use case cited by respondents in the Infosys surveys (Figure 3). Mercedes-Benz, for example, has used generative AI to provide voice assistants for drivers for navigation and vehicle control in its dashboards.

Figure 3. Use cases where manufacturing companies expect the most impact from generative AI

Source: Infosys Knowledge Institute

The other two generative AI use cases of interest in our study are operational efficiency through automation and customer personalization. Ferrari uses generative AI to create car configurations 20% faster and share them with its customers, allowing them to visualize the car and personalize the configuration from interiors to choice of paint and wheels.

US Steel has deployed generative AI to simplify its equipment maintenance function, initially for a fleet of 60 haul trucks. The application will assist maintenance teams by guiding them through truck repairs, order parts, and distill complex information to be shared with references. When fully deployed, the application is expected to reduce the time taken to complete a work order by 20%.

Further use cases

Generative AI has been used effectively at all stages in the product life cycle, not just in product design. In planning, generative AI gives Tesla the ability to automate and accurately forecast demand, and predict material delivery, reducing stock levels and on-hand inventory.

Other companies such as Siemens use generative AI for supply chain management, deploying it to help negotiate contracts, find new suppliers, and identify issues such as environmental and human rights concerns. Analysis of shipping documents and customs declarations helps build a global supplier map for regulatory requirements traceability.

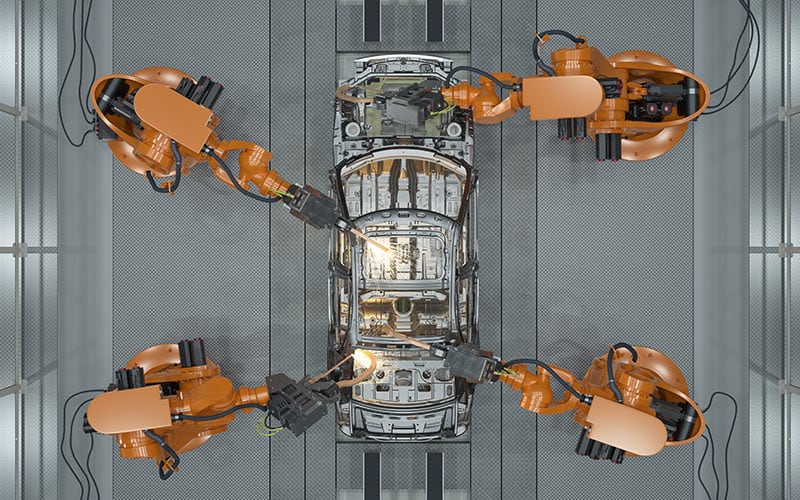

The growth in intelligent machine networking for information and communication tech is a key manufacturing shift of recent years — this is commonly known as the Fourth Industrial Revolution, or Industry 4.0. Under the Industry 4.0 umbrella, generative AI is used in factories for quality control and predictive maintenance For example, Mahindra & Mahindra uses generative AI for robot maintenance. Along with the equipment user manuals, the knowledge residing with maintenance teams is captured, used to train a model, and deployed as a bot, which is then used to troubleshoot machine malfunctions, reducing equipment downtime.

Tesla has used AI in developing autonomous driving for its vehicles: Video captured from cars on the road is used to construct scenarios and train new cars. Similarly, Toyota’s connected vehicles gather data from hundreds of sensors to build models for common maintenance tasks and give timely alerts to its customers.

For end-of-life management, Siemens uses generative AI to sort plastic waste for recycling, deploying a robot picker that autonomously sorts plastics. Generative AI is used to train computer vision to identify objects and program the robot’s movements as part of an integrated solution for circularity.

Leveraging unstructured data

A core foundation for the successful use of generative AI is data, both structured data as well as unstructured data. This includes customer queries and feedback, social media posts, audio, and video. Business value gets boosted when both structured and unstructured data are analyzed together. Warranty management is one area with copious amounts of both structured and unstructured data.

Ford paid $1.9 billion in warranty costs in 2023, with 56 recalls that involved 5.7 million vehicles. Automated visual inspection in its factory is helping Ford reduce its repair and warranty costs. The solution uses deep learning and is trained on both good and defective products at various stages. When deployed, the algorithm can take a go or no-go decision for each part in the shop floor. It is self-learning, taking inputs from manual inspectors.

John Deere collects billions of soil, crop, and weather condition data from 500,000 of its connected farm equipment deployed over more than 325 million acres of land. Soil data is a combination of structured data such as nutrient levels, and unstructured data such as farm images, farmers’ written notes and observations. This combination of structured and unstructured data is fed into a central cloud-based system and analyzed to generate ideas to improve its equipment and farming practices.

Ethical obstacles

Concerns about ethics and appropriate use of generative AI is an ongoing issue. According to Gartner, defensive spending on reducing risk will slow generative AI adoption and diminish returns by 2026. Figure 4 shows the obstacles to generative AI adoption in manufacturing compared with the overall obstacles across industries.

Figure 4. Obstacles to generative AI adoption in manufacturing

Source: Infosys Knowledge Institute

World Intellectual Property Organization (WIPO) has shared its recommendations to protect sharing of confidential information and to avoid IP infringement during usage of generative AI. Some of its recommendations to mitigate the risks in sharing of information are a private cloud for generative AI deployment, employee training on risks, and limited access for specific AI tools to specific team members based on their roles. Risks from IP infringement can be avoided by usage of generative AI tools trained on proprietary or licensed information, documenting the training process for the tools for audit purposes, and avoiding reference to third-party business names, trademarks, and copyright works in prompts.

Our own recommendations for ethical, responsible AI are classified into strategic, tactical, and governance approaches that must work in tandem. Strategically, leaders should choose the AI tool fit for the purpose. Ethical considerations must be designed in, not bolted on as an afterthought. There should be centralized monitoring for all AI projects, with reference playbooks and use case assessments based on risk. From a governance perspective, there should be clear and accessible policies, process guardrails, and management systems for enterprise governance.

Our recommendations for ethical, responsible AI are classified into strategic, tactical, and governance approaches that must work in tandem

Workforce readiness

The manufacturing sector is as ready as the others for its workforce to adopt generative AI. 65% of our study participants are positive towards generative AI adoption (Figure 5). Adecco Group’s annual global workforce study reported similar numbers, with 62% of respondents saying they believe generative AI will positively influence their work. At the same time, they are concerned about the emergence of a class of haves and have-nots in the workforce, depending on the level of access to training on AI tools as executives. Also according to the Adecco study, higher-income employees have better access to AI. Corporates should democratize AI to make it accessible at all levels of hierarchy across the organization to avoid such concerns.

A Harvard Business Review study reported that employees suffered sadness and isolation after their routine tasks were automated by AI. Reskilling is important to make them feel valuable and enrich their work. Workflows should be redesigned around the unique strengths of humans and machines. Mercedes-Benz has invested more than €2 billion to train 600 employees from manufacturing and administration roles to become data and AI specialists. These programs are expanded after seeing the interest among its employees.

Figure 5. Sentiment on workforce readiness to adopt generative AI, by proportion of respondents

Source: Infosys Knowledge Institute

Four recommendations

- Keep humans in the AI loop: Humans trained in the nuances of generative AI will be essential to address the concerns over ethics, bias, explainability, hallucinations, and the variations in the output produced. Reskilling humans with domain knowledge in specific areas will play a key role to fill the demand-supply gap for skilled workforce. At the same time, it will provide employment for those displaced due to automation.

“As the amount of data used and output produced grow exponentially, the number of humans in the loop should also grow, albeit at a much lower rate which will ensure productivity gains. Humans will not only deal with hallucinations, non-standard situations, and conflicts, but will also bring in tacit knowledge,” said Professor Valery Yakubovich, executive director at the Mack Institute for Innovation Management, the Wharton School, during a discussion on the use of generative AI for innovation.

Humans trained in the nuances of generative AI will be essential to address the concerns over ethics, bias, explainability, and hallucinations

- Combine structured and unstructured data for actionable insights: Companies have multiple sources of structured and unstructured data. Combining both these data sources is a challenge. Businesses must identify, classify, and clean both these data types to resolve issues of incomplete data and noise. Generative AI can be used as an engine to combine both and come out with actionable insights for product development and other requirements.

- Multimodal AI combining multiple technologies: Generative AI should not be looked at as an answer for isolated use cases, but integrated solutions that combine multiple technologies for business impact. The integration of computer vision and a robotic arm for plastic sorting to recycle them at Siemens is one such example. IT-OT integration, or the integration of enterprise IT systems such as ERP (enterprise resource planning) and CRM (customer relationship management) to operational technology or OT systems in the shop floor such as the MES (manufacturing execution system) and SCADA (supervisory control and data acquisition) systems will be key to realizing maximum benefits.

- Agentic AI for multi-step autonomous decision making: The next stage for organizations to evaluate and invest in the evolution of generative AI is agentic AI, beyond just content creation. Agentic AI can iteratively solve business problems and take autonomous decisions with multiple steps, working towards a goal, with minimal human intervention only for exceptions.