Artificial intelligence and high tech supply chains

Timely and reliable data processing is essential for supply chains today. Millions of purchase orders, invoices, bills of lading and records are processed every year. To do this efficiently, repeatable processes like these are increasingly automated. But standard robotic process automation can struggle with exceptions, which can be a significant issue in fast moving supply chains.

Managing VUCA

We define high-tech industry in this article as the semiconductor manufacturers, component makers, distributors, original equipment manufacturers, value-added resellers and service providers that implement and embed the software to deploy the product for end users. Figure 1 shows the value chain.

The great irony of any supply chain is that exceptions are the norm.

Volatility, uncertainty, complexity and ambiguity (VUCA) are significant barriers to standardizing and automating processes.

Fluctuating prices can disrupt plans throughout the chain, from the commodity all the way to those of the finished goods — and back again. Additional uncertainty is created by the global nature of today’s supply chains that bring factors beyond control such as forces of nature and politics. The increasingly complex nature of products with embedded intelligence in the form of software adds another level of challenge. Further, technology upstarts are rapidly emerging and challenging incumbents with new products and processes (such as 3D printing or new materials and designs), increasing the ambiguity in planning.

VUCA is particularly challenging in the high-tech industry. The complexity and cutting-edge nature of these products, combined with the short shelf life of the associated technologies, multiply the effect of VUCA. The challenge is to manage these ambiguities at speed with the least amount of human intervention.

AI/ML based decision-making can automate this with agility and accuracy — not only working continuously to do so, but also learning independently with every transaction.

SCOR model and AI applications

The Supply Chain Operations Reference framework, developed by the American Production and Inventory Control Society is a good structure to understand the emergence and application of AI/ML in supply chains. The APICS dictionary defines AI as “computer programs that can learn and reason in a manner similar to humans.” In contrast, conventional programming collects and processes data by algorithms or fixed step-by-step procedures.

The SCOR framework consists of six process categories to represent an end-to-end supply chain: plan, source, make, deliver, return and enable, as shown in Figure 1.

Figure 1. SCOR framework for the high-tech value chain

Figure 2 shows the high-impact use cases for AI adoption under each SCOR process category. The following sections explain the use cases with examples.

Figure 2. Use cases for AI adoption across the supply chain

Plan — ongoing forecasts in real time

The enormous volumes of data that can be managed by AI make it useful for the crucial activity of demand forecasting. Forecasting has its challenges in this industry due to the demand uncertainty, product variety and customization, materials complexity, product innovations, and short response time expected for order fulfillment. But AI can be used to adjust system parameters based on real time sales, seasonal fluctuations and abnormal demand patterns.

With real time information, planning and distribution systems can be reconfigured to be proactive without waiting for specific triggers such as an order placement.

Amazon has used AI to do this in its first fulfillment center in New York City.1 It halved its order fulfillment time from two hours to one in the automated warehouse, along with AI enabled systems to track and measure the factors that improve demand forecasting accuracy. Forecasts are based on real time sales, weather conditions and other external factors by providing continuous system adjustments. With this loop of information, warehouse planning processes were re-engineered to implement self-managing inventory systems, self-driving forklifts and automated sorting.

Source — cognitive processes

Procurement has undergone several waves of technology adoption in its evolution in the past decade. Enterprise resource planning systems became the master system of record for parts. eProcurement leveraged the internet with online product catalogs. Self-service procurement systems empowered category managers to set preset rules for procurement across multiple digital channels, choosing the most appropriate supplier. Robotic process automation improved productivity with bots performing repetitive tasks.

The next step is for AI and ML to help procure materials intelligently. An AI/ML system can understand the context, consolidate information from multiple internal and external sources, identify patterns, and alter the experience for buyers and sellers in the procurement process. Ad hoc procurement of low-value items can be automated with context-aware chatbots. Algorithms analyze spend data with varying levels of sophistication to find patterns, draw inferences and perform near-real time classification to tag purchase orders at the time of creation itself. This helps in timely and accurate spend analysis, speeding up the process from days to minutes.

The invoice workflow for Advanced Micro Devices was automated to avoid processing delays and free up the accounts payable team. An AI bot extracts and analyzes relevant data such as the invoice number, workflow details, comments and action from emails in the invoice mailbox at regular intervals. The system sends emails to approvers based on approval limits and date ranges that are predefined. A consistent experience is provided to the AP team using mobile devices with apps that need not log into the ERP system. Email can be used from mobile phones to approve or reject invoices. The implementation resulted in an 80% reduction in invoice approval time.

Make — improved asset efficiency

AI-based shop-floor control systems analyze high-volume operational data to eventually reduce the cost and cycle time for making products. AI helps in asset management with preventive maintenance, leading to efficient operations. Current status of open orders, shipment and inventory provide ongoing scheduling for dynamic shop-floor assignments.

For example, AI reduced the cost of maintenance and production loss due to unplanned spindle replacement for an automobile maker. This was possible because of the extension in the useful life of the spindle. The carmaker faced unpredictable downtime and unwarranted replacement of spindles on their shop floor. Sensors were used with analytics at the edge for analyzing critical parameters, to raise alerts whenever thresholds were exceeded. An internet of things gateway was used to consolidate and acquire data from multiple systems working on diverse protocols, to ingest the AI engine with data. An AI framework automated the time consuming exploratory analysis and feature extraction to result in a 30% reduction in the manual effort.

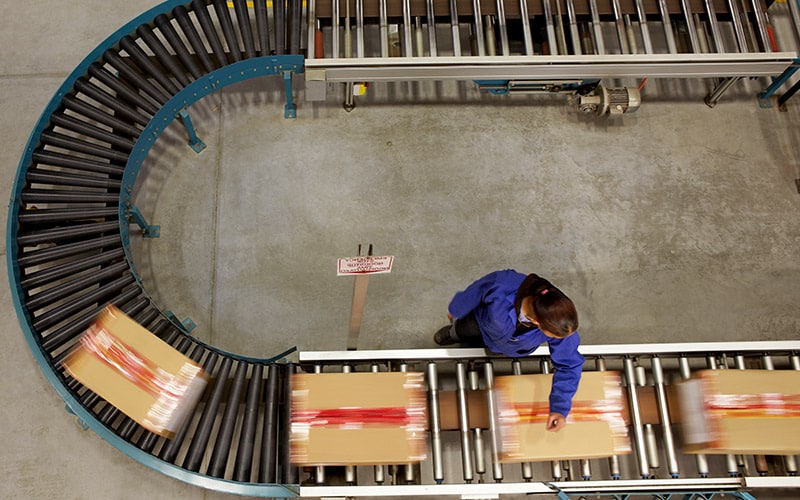

Deliver — cost-effective last mile

AI can analyze and optimize logistics networks efficiently. Positional tracking devices can track fleets precisely in real time. Irregularities identified in a shipment can be proactively addressed to have control over deliveries.

A global mining customer with a $1 billion logistics services business used AI to enhance its freight analytics to provide insights into profitability, safety and performance of the fleet. The AI based decision support system for freight operations analyzed diverse international commercial terms and agreements to suggest the most profitable service for a sales contract. Streamlined freight operations delivered an annual saving of $100 million in bunker and freight costs.

Return — disposition and pricing

According to the United States Postal Service,2 between $113 and $132 billion worth of ecommerce goods were returned back in 2017. Returns amounts to approximately 5% of sales, varying from industry to industry. It is an important function to ensure customer loyalty but with effective cost control.

AI/ML can be used for disposition of goods returned. For every product returned, the decision to be taken is whether to repair and repackage it (up to what extent), whether to sell it as a new item or a used item based on the product’s condition (at what price), or to scrap it. While this area is in its infancy, AI enables optimal large scale decision-making at all stages of managing returned goods, maximizing the revenue from it while minimizing the cost involved. Apple’s Daisy is an example for usage of robotics along with ML for recycling returned products to recover valuable materials. Daisy uses ML for identifying phone models, and can disassemble up to 200 iPhones per hour.

Enable — the virtual backbone

Keeping the technology that forms a supply chain’s backbone healthy is imperative in such a fast moving environment. Manufacturers can take a lesson from telecom service provider Vodafone’s self-healing networks implementation. AI continuously optimizes the underlying network infrastructure to meet evolving customer needs. The algorithm took four hours to identify optimal settings for voice services across 450 mobile phones chosen at random. An engineer would have taken 2.5 months to do the same. Future network traffic is predicted based on historical data and pattern recognition. The predictions have been accurate for the network to self-configure for balance of its load and thereby improve the customer experience.

Start small then scale

Adoption of AI is no longer a question of why but when and how. The primary challenges in AI adoption will be in scaling up small initiatives to a global level and in finding the skills to implement such platforms. Applications developed for one team at a small level may not apply elsewhere due to variations in the way each business unit works. This will call for standardization and re-engineering of processes, applications, and data across divisions and regions before scaling up.

The skills gap is perhaps the main barrier to adoption. While high-tech industries account for a significant proportion of the labor market’s science, technology engineering and mathematics skills, only a small portion of those are trained to develop and deploy AI systems. Furthermore, demand for these skills is growing globally across industries, and traditional education approaches are under strain to deliver.

To succeed with AI, companies should focus on partnering with AI specialists who can work with them to develop in-house talent through engagement in small pilots. These pilots should be scaled up gradually and with caution, each step helping the organization and its nascent AI-trained teams to learn and gain confidence as they make progress.

References

- Amazon’s Robot-Filled New York Fulfillment Center Gives Rivals Another Reason To Worry

- Office of Inspector General, United States Postal Service, “Riding the Returns Wave: Reverse Logistics and the U.S. Postal Service”, April 2018